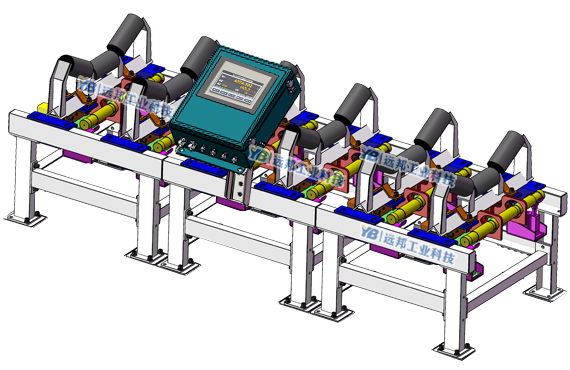

Conveyor Belt Scales

The conveyor belt scales developed by YonBond have an operating accuracy of ≤±0.2% and a maintenance-free period of up to 180 days!

Calibration accuracy: ± ≤0.1%;

Use accuracy: ± 0.2%~0.5%;

Stabilization period: 3~6 months;

Belt Width: 300~2600mm;

Belt Speed: ≤ 5.5m/s;

Material flow rate: ≤ 8000t/h;

Why choose YonBond Conveyor Belt Scales?

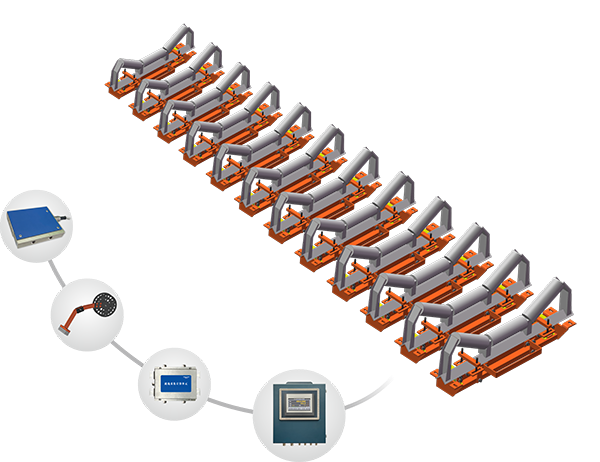

Flexible Configurations

Our conveyor belt scales can be easily configured to meet different accuracy requirements. YonBond offers belt scales with weigh sections consisting of between a 2 to up to 12 idlers and belt widths from 450mm to over 2600mm.

Weighing Accuracy to Fit Your Needs

≤0.2%~0.5% — Ultra-high accuracy for loading, unloading, and custody transfer. 0.5%–1.0% — Ideal for control and in-process weighing. 1.0%–2.0% — Cost-effective, rugged, and reliable for sand, aggregates, and other low-value bulk materials.

Built to Survive

Our conveyor belt scales are engineered with durable, robust construction to withstand extreme conditions and the shock loads of thousands of tonnes per hour, ensuring reliable performance even in the harshest environments.

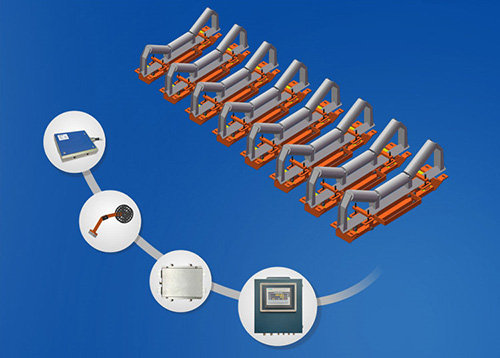

Product composition

The YonBond conveyor belt scale is composed of a weighing display controller, data acquisition and calculation unit, load cells, direct-load weighing units, belt speed sensor, and automatic calibration device.

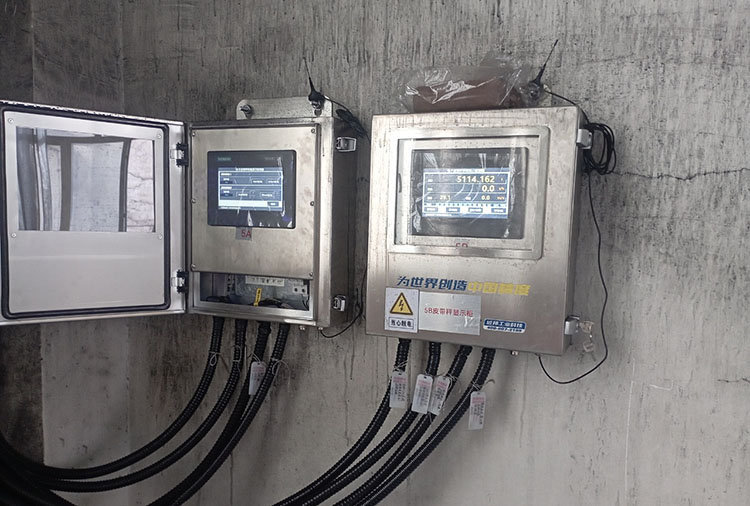

Weighing Indicator

Equipped with a 5-inch or 7-inch color touchscreen plus physical keys, the indicator offers intuitive operation and clear display. The main screen shows real-time cumulative total, instantaneous flow rate, belt speed, flow curve, and other key parameters.

Contact Us

Data Acquisition and Calculation Unit

Each load cell sends its signal individually to the acquisition unit, and each unit operates in dual-channel mode. Preliminary calculations are performed locally, and each unit communicates with the weighing indicator via CAN bus in a daisy-chain configuration.

Contact Us

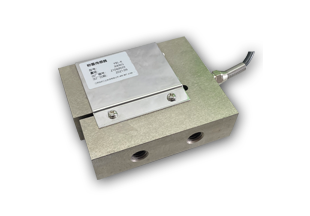

Weighing Load Cells

Equipped with 4–24 high-precision load cells, each featuring a parallelogram-shaped outer frame and a triple-beam internal structure. This design effectively compensates for lateral forces and internal torsion between load cells, ensuring accurate dynamic weighing while minimizing the effects of belt misalignment and off-center material loading.

Contact Us

Direct-load Weighing Unit

Adopts a direct-load, fully-suspended structure that effectively eliminates the effects of off-center loading, lateral forces, and horizontal force interference. This design minimizes the impact of belt misalignment and material discharge deviation on system accuracy. With no dust accumulation areas, the unit is maintenance-free and requires no cleaning. The scale body is treated with sandblasting and powder coating, providing an attractive appearance and excellent corrosion resistance.

Contact Us

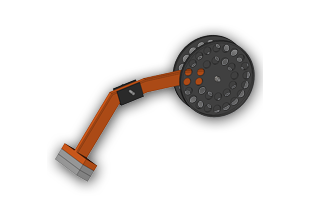

Belt Speed Sensor

A high-precision speed sensor specifically designed for belt scales, featuring a heavy-duty, rubber-coated speed roller to prevent slippage and ensure accurate, distortion-free belt speed measurement.

Contact Us

Automatic Calibration Device (Optional)

Allows the conveyor belt scale to be calibrated either locally or remotely. An AI-based automatic calibration system is also available, enabling real-time, online calibration for enhanced accuracy and convenience.

Contact UsModel Comparison

YonBond conveyor belt scales are available in configurations with 2, 4, 6, 8, 10, or 12 idlers. Different models offer varying accuracy levels and maintenance-free intervals. Please contact YonBond for assistance in selecting the most suitable model for your application.

Model

- Calibration Accuracy: ≤±0.1%

- Operating Accuracy: ≤±1%

- Maintenance-free Interval: 10

- Number of Weighing Units: 2

- Number of Load Cells: 4

- Number of Channels: 1

Model

- Calibration Accuracy: ≤±0.1%

- Operating Accuracy: ≤±0.5%

- Maintenance-free Interval: 15 days

- Number of Weighing Units: 4

- Number of Load Cells: 8

- Number of Channels: 1

Model

- Calibration Accuracy: ≤±0.1%

- Operating Accuracy: ≤±0.5%

- Maintenance-free Interval: 30

- Number of Weighing Units: 6

- Number of Load Cells: 12

- Number of Channels: 6

Model

- Calibration Accuracy: ≤±0.1%

- Operating Accuracy: ≤±0.5%

- Maintenance-free Interval: 60

- Number of Weighing Units: 8

- Number of Load Cells: 16

- Number of Channels: 8

Model

- Calibration Accuracy: ≤±0.1%

- Operating Accuracy: ≤±0.2%

- Maintenance-free Interval: 90

- Number of Weighing Units: 10

- Number of Load Cells: 20

- Number of Channels: 10

Model

- Calibration Accuracy: ≤±0.1%

- Operating Accuracy: ≤±0.2%

- Maintenance-free Interval: 180

- Number of Weighing Units: 12

- Number of Load Cells: 24

- Number of Channels: 12

Global Applications

YonBond has over 5,000 conveyor belt scale installations worldwide, spanning Asia, Africa, Australia, North America, and South America. Key industries include coal washing plants, power plants, ports and terminals, cement plants, and coking plants. The following are selected case studies. For more examples, please contact YonBond.

神华国能宝清煤电化有限公司

- 项目地点:黑龙江省·双鸭山市

- 项目数量:4套高精度皮带秤

- 产品型号:YB-GZK-NT/8

- 皮带宽度:1400mm

- 精度要求:0.2级

永城煤电控股集团有限公司

- 项目地点:河南省·永城市

- 项目数量:2套防爆高精度皮带秤

- 产品型号:YB-GZK-NT/8

- 皮带宽度:1400mm

- 精度要求:0.2级

安徽安庆港中心港区石门湖

- 项目地点:安徽省·安庆市

- 项目数量:4套高精度皮带秤

- 产品型号:YB-GZK-NT/8

- 皮带宽度:1200mm

- 精度要求:0.2级

国能中卫发电有限公司

- 项目地点:宁夏·中卫市

- 项目数量:4套高精度皮带秤

- 产品型号:YB-GZK-NT/8

- 皮带宽度:1600mm、2200mm

- 精度要求:0.2级

中煤能源新疆煤电化有限公司

- 项目地点:新疆·昌吉

- 项目数量:4套防爆高精度皮带秤

- 产品型号:YB-GZK-NT/8

- 皮带宽度:1200mm

- 精度要求:0.2级

海南八所港务有限责任公司

- 项目地点:海南省·三亚市

- 项目数量:2套高精度皮带秤

- 产品型号:YB-GZK-NT/6

- 皮带宽度:1200mm

- 精度要求:0.2级